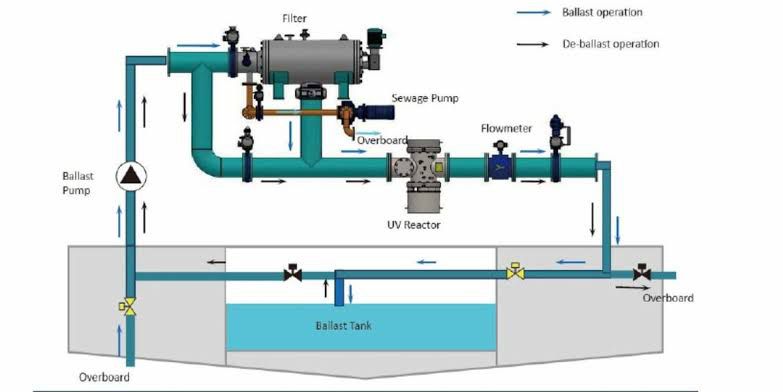

Ballast water treatment is an essential maritime safeguard, preventing ships from unintentionally transporting invasive species – including plankton, larvae, bacteria, and viruses – between global ecosystems during routine ballasting operations. Driven by stringent international regulations like the IMO Ballast Water Management Convention (BWM Convention) and US Coast Guard (USCG) standards, effective treatment before discharge is now a fundamental operational requirement. Modern Ballast Water Treatment Systems (BWTS or BWMS) typically employ a robust two-stage process: initial physical separation (using filters or cyclonic separators) removes larger organisms (>50µm) and sediments, followed by critical disinfection to neutralize remaining pathogens. While technologies like electrochlorination (generating bleach from seawater) or chemical injection are used, Ultraviolet (UV) radiation has emerged as the leading solution due to its chemical-free operation, immediate effect, and compact design.

The effectiveness of UV ballast water treatment hinges entirely on its core component: the Medium-Pressure Ultraviolet (MPUV) Lamp. These lamps are the system's energetic heartbeat, generating the precise, intense UV-C light (200-300 nm wavelength) required to inactivate organisms by destroying their genetic material as water flows through reactors. However, UV lamps are critical consumables; their output inevitably degrades over time. Subpar performance or failure isn't merely inconvenient – it directly risks non-compliance with IMO D-2/USCG standards, potentially leading to operational shutdowns, significant penalties, and ecological harm. This is why sourcing high-performance MPUV lamps from dedicated manufacturers like Fiver Environment Group Ltd is paramount. As professional manufacturers specializing in lamps engineered specifically for the demanding environment of BWTS/BWMS, they provide the reliable replacements and innovative custom solutions necessary to ensure systems operate at peak efficiency and maintain consistent compliance.

Understanding the Science: How UV Lamps Power Effective Ballast Water Treatment

Before diving into solutions, let's solidify the why:

1>The Mechanism: MPUV lamps emit a broad spectrum of UV light, including the germicidal range (~254 nm is peak for DNA/RNA damage). This radiation penetrates organism cells, damaging their genetic material and rendering them unable to reproduce or infect. This is primarily inactivation, not necessarily instant killing.

2>The Challenge: Ballast water varies immensely – turbidity, salinity, organic load, and organism type/size all impact the UV dose (intensity x exposure time) required for effective treatment. MPUV lamps are favored for their high intensity and polychromatic output, which is effective against a wider range of organisms compared to Low-Pressure (LPUV) lamps.

3>The Consequence of Failure: An underperforming lamp delivers insufficient UV dose. This can lead to:

Regulatory Non-Compliance: Failing port state control inspections, leading to fines, delays, detentions, and reputational damage.

System Malfunctions: BWTS sensors detect inadequate UV intensity, triggering alarms, flow reductions, or complete system shutdowns – disrupting schedules and causing downtime.

Increased Operational Costs: Premature lamp failure means more frequent replacements. Inefficient lamps consume more power. Downtime costs money.

OEM Warranty Concerns: Using uncertified or incompatible lamps can void warranties on expensive BWTS equipment.

So Choosing a reliable Medium Pressure UV lamp supplier is crutial.

Fiver Environment Group Ltd: Manufacturing Precision for Global Compliance

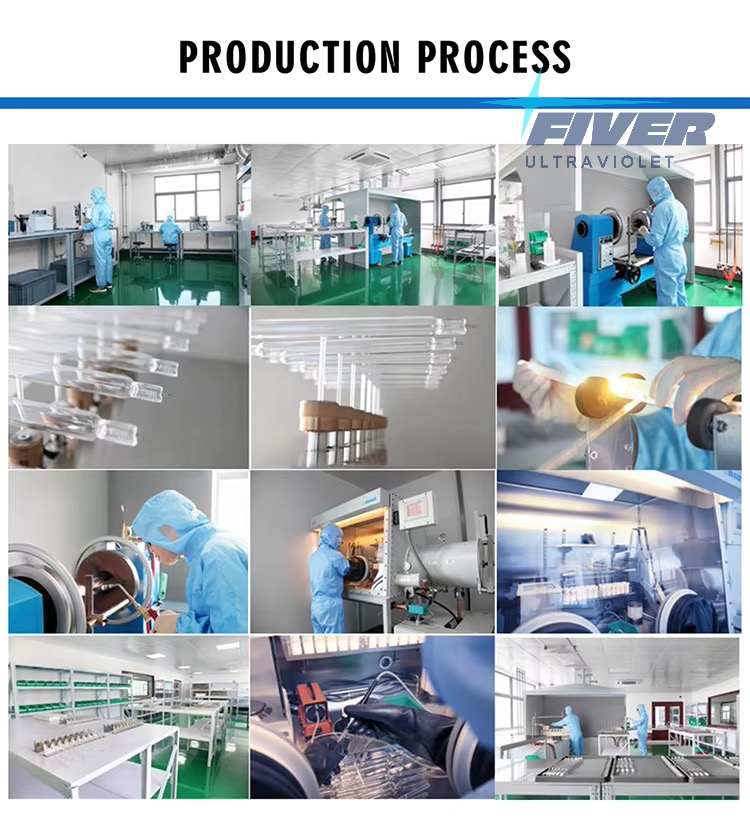

At Fiver, we understand these stakes intimately. We focus exclusively on the engineering and manufacturing of UV lamps for critical water treatment applications, with ballast water as a core specialty. Our state-of-the-art facility combines advanced technology, rigorous quality control, and deep application knowledge to deliver lamps you can trust implicitly.

Core Solution 1: Precision Engineered Replacement Lamps for All Major BWTS/BWMS Brands

Don't compromise with generic or questionable "equivalents." We manufacture exact-performance replacement MPUV lampsdesigned to meet or exceed the specifications of original equipment manufacturer (OEM) lamps for a vast array of systems.

We offer reliable drop-in replacements for UV lamps used in systems including (but not limited to):

| BWTS/BWMS MANUFACTURER | COMMON SYSTEM NAME(S) | WHY CHOOSE FIVER REPLACEMENT LAMPS? |

| Optimarin | Optimarin Ballast System (OBS) | Direct equivalents ensuring optimal UV transmittance & flow rates. Maintains system calibration. |

| Alfa Laval | PureBallast 3, PureBallast 3 EX | Precise spectral output & electrical characteristics for flawless integration & performance. |

| Wärtsilä | Aquarius UV, UVi Ballast | Engineered for the specific reactor geometries and control systems. Guaranteed intensity profiles. |

| Evoqua | SeaCURE (formerly Calgon) | Matching quartz sleeve specifications and electrode design for reliable sealing and output. |

| BIO-UV | BIO-SEA | Tailored replacements maintaining the unique performance requirements of the BIO-SEA reactors. |

| Siemens (Xylem) | UV Ballast (formerly Trojan Marinex) | Compatibility assured for both older and newer generation systems. |

| Headway Technology | OceanGuard | Reliable lamps supporting the growing fleet equipped with OceanGuard systems. |

| JFE Engineering | JFE BallastAce | Precision replacements ensuring consistent treatment efficacy under varying conditions. |

| DESMI | OCEAN GUARD | Designed to meet the specific demands of the OCEAN GUARD BWMS. |

| Other Leading Brands | Contact Us | We continuously expand our portfolio. If you use it, we likely make the lamp or can! |

Our Replacement Lamp Promise:

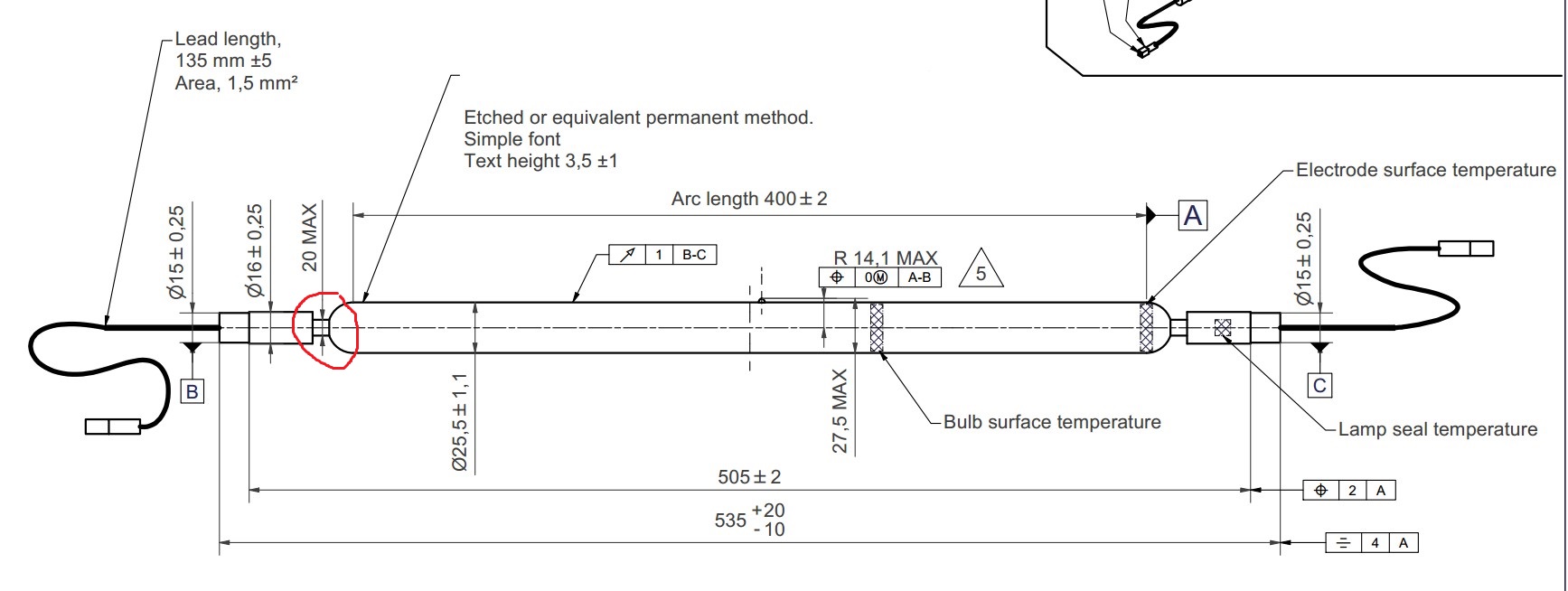

OEM-Equivalent Performance: Electrical specs (voltage, current, wattage), physical dimensions (arc length, overall length, diameter, base type), spectral output, and UV intensity profiles meticulously matched.

Superior Quality Construction:

Premium Quartz Tube: High-purity fused silica quartz ensures maximum UV transmittance and withstands thermal shock and chemical exposure.

Robust Electrodes & Seals: Engineered for longevity under constant vibration, thermal cycling, and the harsh marine environment.

Precise Gas Fill & Dosing: Critical for consistent UV output and lifespan.

Extended Operational Lifespan: Optimized manufacturing processes and materials mean fewer lamp changes, reducing maintenance costs and downtime.

Rigorous Quality Assurance: Every batch undergoes stringent electrical, dimensional, and performance testing (including spectral analysis where applicable) to guarantee reliability.

Global Stock & Swift Delivery: Minimize vessel downtime with readily available stock for popular models and efficient logistics.

Core Solution 2: Unleashing Innovation with Custom UV Lamp Engineering

Beyond replacements, customization is our true forte. Standard solutions don't always fit unique challenges or innovative BWTS designs. This is where Fiver Environment Group Ltd shines.

We collaborate directly with you to design, engineer, and manufacture bespoke MPUV lamps tailored precisely to your requirements:

Custom Physical Dimensions: Need a specific arc length, overall length, outer diameter (OD), or base configuration (e.g., R7s, G12, proprietary bases)? We manufacture to your exact drawings or specifications.

Custom Electrical Parameters: Require unique voltage, wattage, current, or cold/hot impedance characteristics? Our engineering team designs lamps optimized for your power supply and control system.

Custom Spectral Output: Tailoring the UV output spectrum (emphasizing specific wavelengths) can enhance efficacy against particular organisms or improve performance in challenging water qualities (e.g., high turbidity or humic acid content).

Enhanced Performance Features: Need higher initial UV output, faster warm-up times, or exceptional vibration resistance? We can engineer these attributes in.

Reverse Engineering & Sample Matching: Have an existing lamp (OEM or otherwise) that works well or needs replicating? Send us the sample, and we will meticulously analyze and reproduce it, often with improvements in longevity or performance.

Application-Specific Optimization: Designing a new BWTS or upgrading an existing one? Partner with us early. We provide expert consultation on UV lamp requirements, reactor design considerations for optimal UV dose delivery, and prototype development.

Fiver's Advantage: Beyond the Product

Choosing Fiver Environment Group Ltd means partnering with experts committed to your success:

Deep Domain Expertise: We live and breathe UV technology for water treatment. Our team understands the nuances of ballast water chemistry, organism inactivation kinetics, BWTS hydraulics, and marine operational challenges. We speak your technical language.

Vertical Manufacturing Control: As the direct manufacturer, we control the entire process – from sourcing premium raw materials to final QC testing. This eliminates middlemen, ensures consistent quality, and allows for greater flexibility and cost-effectiveness.

Unmatched Flexibility & Responsiveness: Custom orders aren't an exception; they're our specialty. We thrive on solving unique challenges and delivering solutions faster than traditional supply chains.

Proactive Support & Collaboration: We offer technical support beyond the sale. Consult with our engineers on lamp selection, system troubleshooting, or optimizing your maintenance schedules.

Commitment to Compliance: Our lamps are engineered to help you meet and maintain IMO D-2 standards, USCG Type Approval requirements (when used within a certified system according to OEM guidelines), and other regional regulations.

Global Reach, Local Understanding: We serve a worldwide clientele – shipowners, operators, fleet managers, shipyards, and BWTS service providers – understanding diverse operational needs and logistical demands.

Addressing Common Industry Pain Points

"OEM Lamps are Too Expensive and Lead Times are Long": Fiver provides high-quality, reliable alternatives at competitive prices, often with better availability and shorter lead times, especially for custom orders.

"I Can't Find Replacements for My Older/Proprietary System": Our customization and reverse engineering capabilities are the solution. Send us the sample or specs.

"I'm Worried About Compatibility and Voiding Warranty": Our replacements are engineered as direct equivalents. We provide detailed specifications and documentation. While lamp warranties are ours, using high-quality direct equivalents like ours rarely voids overall BWTS warranties – consult your OEM agreement, but we provide the confidence of exact performance.

"I Need Lamps for a New BWTS Design or Retrofit": We are the ideal partner for collaborative development, providing lamp expertise and rapid prototyping.

Ensuring Peak Performance: Best Practices for UV Lamp Management

Maximize your investment and ensure compliance:

Strict Adherence to Replacement Schedules: Don't wait for failures or alarms. Replace lamps based on OEM recommendations or Fiver's guidance, typically every 3000-4,000 operational hours (or annually), whichever comes first. Monitor system UV intensity readings.

Proper Handling & Installation: UV lamps are precision instruments. Always wear gloves (oils from skin damage quartz), avoid impacts, and follow correct installation procedures (cleaning quartz sleeves, ensuring proper seating/seals).

Keep Quartz Sleeves Clean: Fouling on the quartz sleeve drastically reduces UV transmittance. Implement regular sleeve inspection and cleaning protocols as per your BWTS manual.

Maintain Power Supply Stability: Ensure stable voltage and current supply to the lamps as per specifications. Fluctuations can shorten lamp life.

Source Wisely: Partner with a reputable, technical manufacturer like Fiver Environment Group Ltd. Avoid uncertified, low-quality lamps that risk compliance and system performance.

Illuminate Your Path to Compliant and Efficient Operations with Fiver

Your ballast water treatment system is only as strong as its UV lamps. Choosing Fiver Environment Group Ltd means choosing quality, reliability, expertise, and flexibility. Whether you require dependable replacements for scheduled maintenance or a groundbreaking custom solution, we have the capability and commitment to deliver.

Don't let UV lamps be your operational bottleneck or compliance risk.

➡️ Explore Our Extensive Replacement Lamp Catalog: Find the exact match for your BWTS/BWMS.

➡️ Unlock Custom Solutions: Have a unique requirement? Our engineering team is ready to collaborate.

➡️ Get Expert Advice & a Competitive Quote: Contact our technical sales team today to discuss your needs.

Fiver Environment Group Ltd: Powering Clean Seas, One Precision UV Lamp at a Time.

Post time:2025-06-11