365nm UV Lamp High Intensity UV Curing Lamp 3KW Wholesale

365nm UV Lamp High Intensity UV Curing Lamp 3KW Wholesale

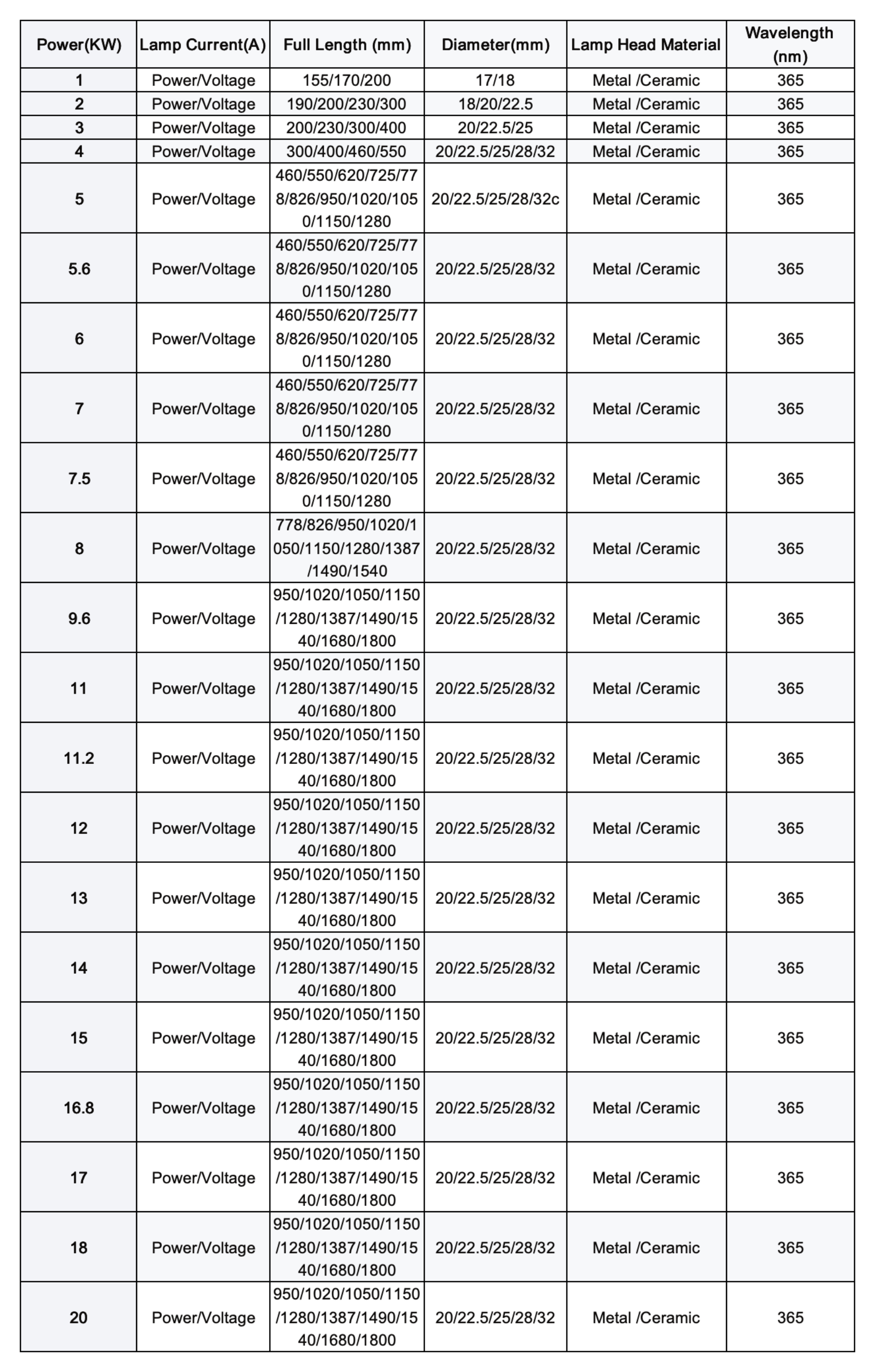

Technical Parameters for Fiver's 365nm UV Lamps

| Fiver 3KW UV Mercury Lamp Parameters | |||||||

| Power | Input Voltage | Full Length mm | Arc Length mm | Lamp Voltage | Lamp Current | Tube Diametermm | Lamp Base Material |

| 3KW | 220V | 155 | 55 | 150-160V | 18A | 17 | Ceramic or Metal |

| 170 | 70 | 18 | |||||

| 230 | 130 | 22.5 | |||||

| 300 | 200 | 25 | |||||

| 335 | 235 | 22.5 | |||||

| 380V | 155 | 55 | 650-700V | 4.5A | 17 | ||

| 170 | 70 | 18 | |||||

| 230 | 130 | 22.5 | |||||

| 300 | 200 | 25 | |||||

| 335 | 235 | 22.5 | |||||

Fiver Offer 365nm UV Curing Lamp Customization

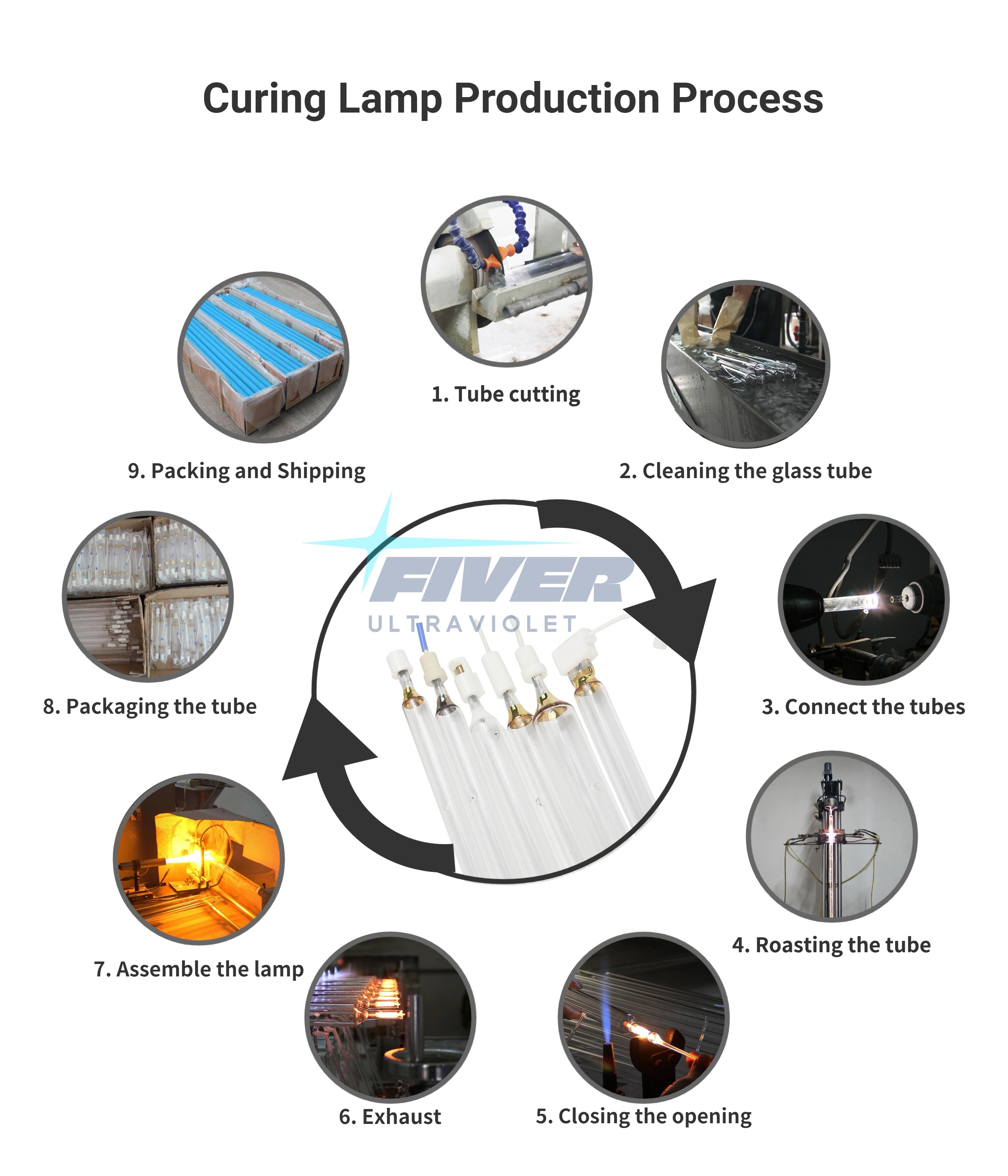

How Are UV Lamps Made?

Characteristics of 365nm UV Light :

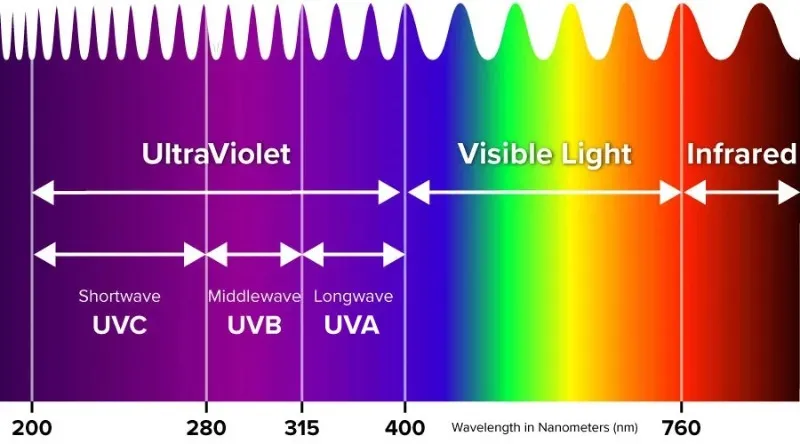

365nm UV light, also known as long-wave UV light, or UVA light. is a specific wavelength within the ultraviolet spectrum.It possesses several key characteristics that make it useful in various applications:

1. Wavelength Characteristics:

The 365nm ultraviolet light falls within the category of long-wave ultraviolet light (UVA). In the classification of ultraviolet light wavelengths, the wavelength range of UVA is from 320 to 400nm, and 365nm is near the middle of this interval. This wavelength makes it longer than the wavelengths of medium-wave ultraviolet light (UVB, with a wavelength range of 280 - 320nm) and short-wave ultraviolet light (UVC, with a wavelength range of 100 - 280nm).

One advantage brought by the long wavelength is its relatively good penetrability. For example, it can penetrate some thin materials such as plastic films and glass. In some application scenarios, such as conducting fluorescence detection on items sealed in transparent packaging, the 365nm ultraviolet light can penetrate the packaging to excite the fluorescence reaction of the substances inside.

2. Energy Characteristics:

According to the photon energy formula E = hc/λ (where E is the photon energy, h is Planck's constant, c is the speed of light, and λ is the wavelength), the 365nm ultraviolet light has specific energy. Its energy is sufficient to enable the electrons of many substances to jump from the ground state to the excited state. However, compared with ultraviolet light of shorter wavelengths, its energy is not so high as to overly damage the substance structure.

This moderate energy enables the 365nm ultraviolet light to effectively transfer energy to the electrons in fluorescent substances when exciting fluorescence reactions, without causing overly violent chemical reactions such as the breaking of chemical bonds in the substances. For example, in the excitation process of fluorescent dyes, the 365nm ultraviolet light can make the electrons in the dye molecules jump, creating conditions for the generation of fluorescence while maintaining the relative integrity of the dye molecule structure.

3. Excitation Characteristics

The 365nm ultraviolet light performs excellently in exciting fluorescence reactions. It can excite many substances with fluorescent properties to produce fluorescence. This is because its energy matches the energy level differences of many fluorescent substances, allowing the electrons of these substances to absorb energy and jump to the excited state. - When the electrons return from the excited state to the ground state, they will release energy and produce fluorescence. Moreover, when the 365nm ultraviolet light is used as an excitation light source, the wavelength of the generated fluorescence is usually within the visible light range, which enables us to directly observe the fluorescence phenomenon with the naked eye. For example, in fluorescence detection experiments, many fluorescent substances used for labeling biological molecules will emit different colors of fluorescence under the excitation of 365nm ultraviolet light, which is used to detect the existence, distribution, etc. of biological molecules.

4. Relative Safety to Humans and the Environment

Compared with short-wave ultraviolet light (UVC), the 365nm ultraviolet light causes relatively less harm to humans. UVC can directly damage the DNA and RNA in cells, while the 365nm ultraviolet light has lower energy and causes relatively minor damage to human skin and eyes under short-term exposure. However, long-term exposure may still have certain adverse effects on the skin and eyes, such as skin aging and eye dryness. - In terms of the environment, the 365nm ultraviolet light also has a relatively small impact. It does not cause serious damage to environmental elements such as the ozone layer like short-wave ultraviolet light does. Under normal usage conditions, it causes relatively less interference to the surrounding ecological environment.

5. Background Interference Characteristics in Fluorescence Detection

The 365nm ultraviolet light is invisible light, which has a great advantage in fluorescence detection. During the detection process, it does not produce intense background light interference like visible light does. When using the 365nm ultraviolet light to excite fluorescent substances, what we mainly see is the fluorescence emitted by the fluorescent substances, rather than the visible light rays produced by the excitation light source itself. This makes the fluorescence signal easier to identify and analyze. - This low background interference helps to improve the sensitivity and accuracy of fluorescence detection, enabling more precise detection of whether substances have fluorescent properties, as well as the intensity and color of the fluorescence, etc. It has important application values in many fields such as material analysis and biomedical detection.

Applications of 365nm ultraviolet light:

365-nm ultraviolet light has different application scenarios depending on its energy density. such as fluorescence detection, curing and disinfection.

1. Application Scenarios of Low Energy Density

Fluorescence Detection and Analysis

Observation of Biological Samples: In the biomedical field, when 365-nm ultraviolet light irradiates biological samples at a low energy density, it can excite the fluorescent molecules (such as fluorescent proteins, fluorescent dyes, etc.) labeled in the samples to produce fluorescence. For example, in cell imaging experiments, researchers can use 365-nm ultraviolet light with a low energy density to observe the distribution of specific proteins within cells. This low-energy irradiation will not cause obvious damage to the cell structure and function, while providing sufficient excitation energy to make the fluorescent proteins emit fluorescence, thus helping scientists understand the physiological processes of cells.

Identification and Conservation of Cultural Relics: For the pigments, papers, and other materials in cultural relics, 365-nm ultraviolet light with a low energy density can be used to detect their fluorescence characteristics. Many ancient pigments contain specific mineral or organic components that will produce unique fluorescence reactions when excited by low-energy ultraviolet light. By observing these fluorescences, it can assist in judging the authenticity, age of cultural relics, and the matching of materials during the restoration process. Moreover, the low energy density can avoid causing damage to cultural relics, as the materials of cultural relics are usually fragile and excessive energy may lead to fading of pigments, aging of papers, and other problems.

Water Quality Detection: In the field of environmental science, 365-nm ultraviolet light with a low energy density can be used to detect organic pollutants in water. Some organic compounds in water (such as polycyclic aromatic hydrocarbons, pesticide residues, etc.) will produce fluorescence when excited by low-energy ultraviolet light. Through fluorescence detection equipment, qualitative and quantitative analyses of these pollutants in water bodies can be carried. Since a low energy density is adopted, it will not cause chemical reactions of the organic pollutants in water to change their properties, thus being able to more accurately reflect the pollution status of water bodies.

Fluorescence Anti-counterfeiting Applications: In the field of commodity anti-counterfeiting, 365-nm ultraviolet light with a low energy density can be used to excite fluorescence anti-counterfeiting marks. Many high-end commodities (such as branded clothing, electronic products, cosmetics, etc.) have fluorescence anti-counterfeiting identifications on their packaging or the products themselves. When consumers irradiate with 365-nm ultraviolet light at a low energy, the anti-counterfeiting identification will emit fluorescence of specific colors and patterns to verify the authenticity of the product. This low-energy ultraviolet light irradiation can effectively excite the fluorescence anti-counterfeiting marks without causing damage to the product or packaging materials.

2. Application Scenarios of Medium Energy Density

- Surface Modification of Materials: In the field of materials science, 365-nm ultraviolet light with a medium energy density can be used for the surface modification of materials. For example, in the treatment of plastic surfaces, ultraviolet light irradiation can cause the molecular chains on the plastic surface to undergo cross-linking reactions, improving the surface hardness, wear resistance, and chemical corrosion resistance. By controlling the energy density of 365-nm ultraviolet light to a medium level, the degree of surface modification can be precisely adjusted, optimizing the surface properties of plastics while avoiding damage to the internal structure of the materials due to excessive energy.

- Initiation of Photochemical Reactions: For some photochemical synthesis reactions, 365-nm ultraviolet light with a medium energy density can be used as an initiator. For example, in the synthesis of certain organic compounds, this ultraviolet light can provide sufficient energy to initiate the reaction of the active groups (such as double bonds, carbonyls, etc.) of the reactant molecules. By reasonably adjusting the energy density, the rate and selectivity of the reaction can be controlled to achieve the efficient synthesis of the target compound. Moreover, compared with traditional heating-initiated reactions, photochemical-initiated reactions have the advantages of mild reaction conditions and fast reaction speed.

- Drying of Inks and Coatings: In the printing and coating industries, 365-nm ultraviolet light with a medium energy density can be used for the drying of inks and coatings. When ultraviolet light irradiates the surface of inks or coatings, it can prompt the rapid evaporation of the solvents and the preliminary curing of the resin components. This energy density of ultraviolet light can ensure the drying effect while avoiding quality problems such as wrinkling and cracking on the surface of inks or coatings due to excessive energy. Moreover, compared with natural drying or thermal drying methods, ultraviolet light drying is faster and can improve production efficiency.

3. Application Scenarios of High Energy Density

-Deep Curing of UV Glues and Sealants: In the industrial manufacturing field, 365-nm ultraviolet light with a high energy density is often used for the deep curing of UV glues and sealants. For some components that require high-strength bonding or sealing (such as electronic devices, optical instruments, etc.), the glues or sealants need to be completely cured in a short time and with sufficient curing depth. High-energy-density ultraviolet light can penetrate the layers of glues or sealants, enabling the internal photoinitiators to react fully, thus achieving deep curing. This curing method can ensure the reliability and durability of bonding or sealing.

-Rapid Prototyping and Processing of Materials: In 3D printing and rapid prototyping technologies, 365-nm ultraviolet light with a high energy density can be used for the rapid prototyping of photocurable resin materials. By focusing ultraviolet light on specific areas of the resin materials, high-energy-density irradiation can make the resin solidify rapidly, building three-dimensional objects layer by layer. This technology can achieve the rapid manufacturing of complex shapes, and since the ultraviolet light curing speed is fast, the molded objects have high precision and good mechanical properties.

- Sterilization and Disinfection Applications: In the fields of medical health and food processing, 365-nm ultraviolet light with a high energy density can be used for sterilization and disinfection. Ultraviolet light can destroy the DNA or RNA structures of bacteria, viruses, and other microorganisms, thereby making them lose their activity. High-energy-density irradiation can achieve efficient sterilization in a short time, reducing the harm of microorganisms to human health and food safety. However, in actual applications, attention should be paid to avoiding harm to humans and beneficial microorganisms.