110V/230V 75W UV Bulb Ballast for T5 UVC Germicidal Lamps

110V/230V 75W UV Bulb Ballast for T5 UVC Germicidal Lamps

Product Specifications for 75W UV Bulb Ballast

Operating Voltage Range | 99-264 |

Max Input Power | 90W |

Max Input Current | 0.40A @ 230V 0.83@120V |

Lamp Power | 1*Lamp: 40-80W; 2*Lamps: 10-35W |

Lamp Current | 0.38-0.43A |

Operating Frequency | 50-70KHZ |

Preheat Time | 3.0-4.0 S |

Preheat Current | 0.42-0.52A |

Power Factor | ≥ 0.97 |

Efficiency | >90% |

Total Harmonic Distortion | <15% |

Crest Factor | <1.7 |

Ambient Humidity | 5%-85% |

Ambient Temperature | -15-40℃ |

Max Case Temperature | 70℃ |

Case Material | Aluminum Shell |

Safety Norm | EN61347-1-2-3, EN62493 |

LVD Norm | Low voltage Directive 2014/35/EU |

EMC Norm | EN55015, EN55014, GB17743, GB17625, EN61000-3-2 |

Certificates | CE/UL/CCC |

Features of the uv electronic ballasts:

1> Long Life span, the switching cycles for this 75W UV Ballast is up to 50000 times, we offer a warranty for 5 years.

2> Money saving, the uv lamp electronic ballasts is energy efficient, save the user money by minimizing energy waste.

3> Compact in size and light in weight, uv electronic ballasts are smaller and lighter than magnetic uv ballasts.

4> Constant power disign, the Electronic UV Ballasts can continuously adjust power at different settings, more stable in operation and better disinfection effects.

5> Quiter operation, the electronic uv bulb ballasts are more quiter than megnetic ones.

6> Dimming capabilities, uv electronic ballasts can be dimmed. suitable for different uv lamps and different application scenarios.

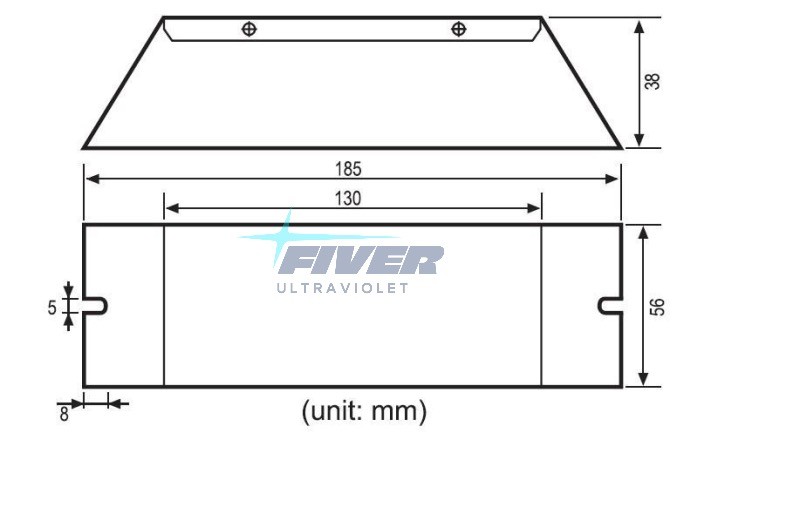

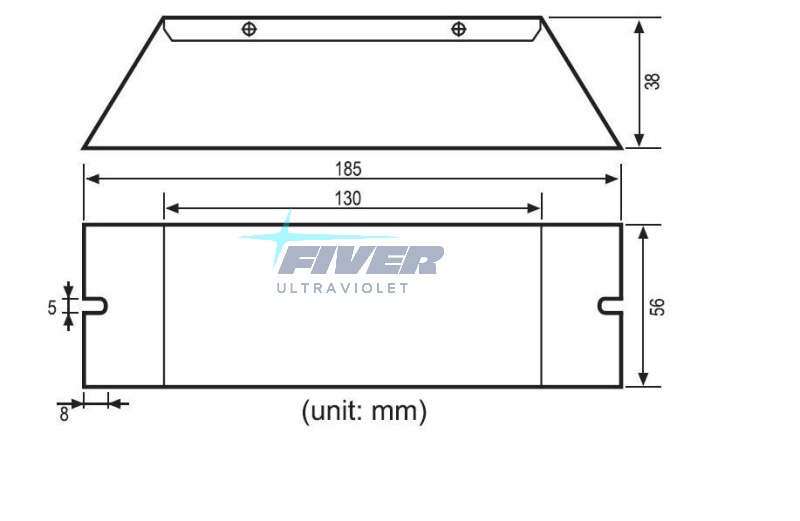

Dimension for this 75W UV Ballast

Size: 185*56*38mm Carton size: 460*270*190mm( 27PCS Load)

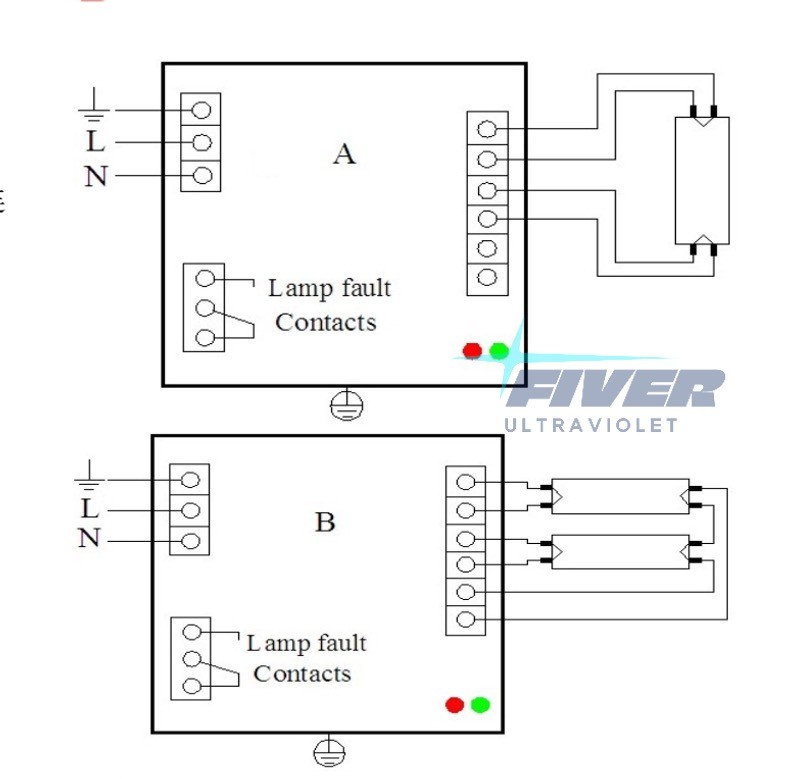

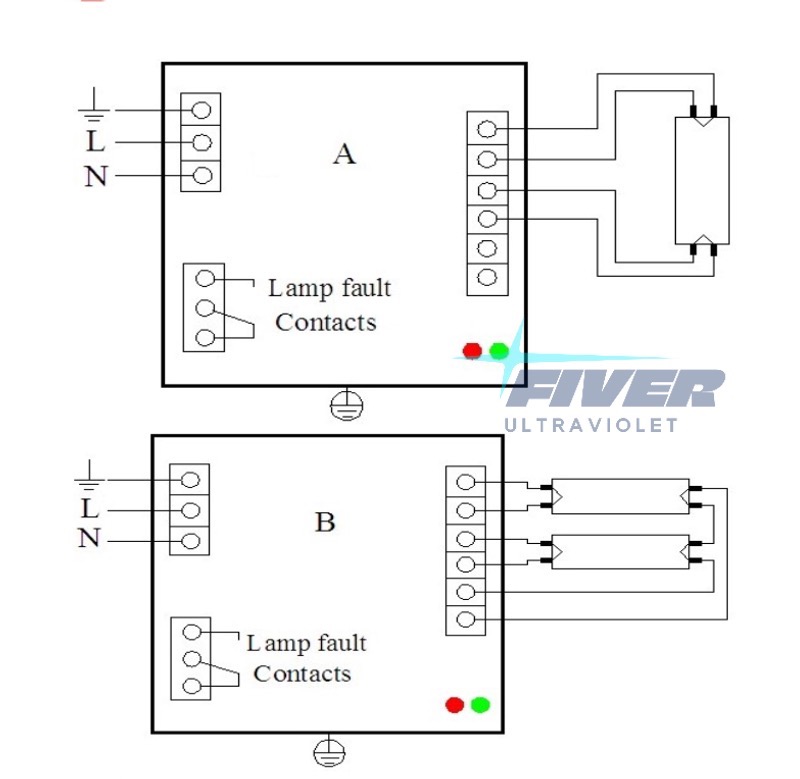

Wiring Diagram for uv electronic ballast

This 75W Electronic UV Bulb Ballast has two wiring methods:

Wiring diagram A: 1 Lamp: GPH1148T5, GPH1554T5, GPH1630T5, TUV64T5, G64T5

Wiring diagram B: 2 Lamps: GPH793T5, GPH843T5, TUV36T5, G36T5

Cautions:

1. Please make sure the power is off when you install or maintain the ballast

2. The distance between ballast and lamp tube should no longer than 5M.

3. The suggested wire specific: diameter 0.5-1mm, wire stripping 0.8-1mm

4. The aluminum shell should be grounded.

Applications for uv lamp electronic ballast